Written by Ian Lee.

Sometimes a bike appears in our inbox that is hard to write a post on. It’s not so much the bike is built in bad taste, or lacks description from the builder, it’s because the damn thing has so many features it can be hard to know where to start. Today’s bike falls into this category, it is a cacophony of build aspects, all vying for attention at the same time. Coming out of the Rusty Bolt Garage in Santa Fe, this Yamaha RD400 has been built with everything “either upgraded, replaced, or repaired on this baby.” And what a beautiful baby it is.

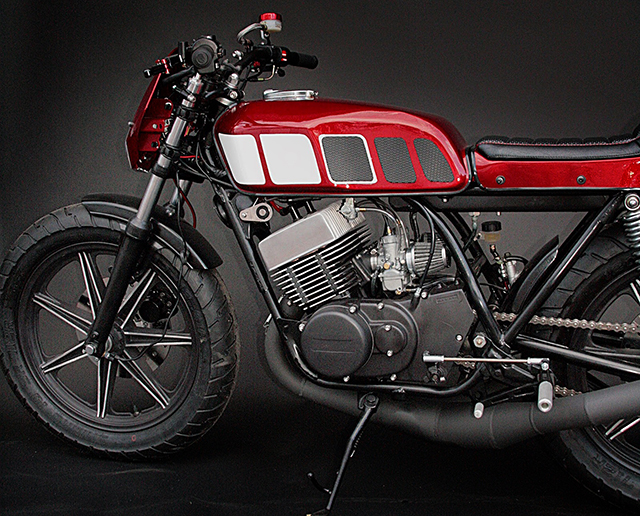

Starting at the heart of the bike, the engine has been fully rebuilt to almost original specifications, with a 66mm rebore increasing the cc’s to 425. While the engine was stripped down, the cylinder heads, cylinders and stock Mikuni carbs were sent to Vapor Blast Solutions to be “treated to a nice polish.” On reassembly, the engine cases and cylinders were treated to a fresh coat of black, with the fins sanded back to match the aesthetics of the rims.

Once the carbs came back from being blasted, they were rebuilt using new components where ever required. The Mikunis paired up with Pod filters. The Yamaha ‘Autolube’ system was kept on the bike, given a full rebuild and all oil lines replaced. The exhaust duties are taken care of by a custom setup, running DG expansion chambers, with one pipe per cylinder.

While the engine was out, the frame was detabbed and powdercoated in satin black. A new electronics tray was mounted, to suit the reworked wiring harness. To suit the clean ‘lightweight’ look the build was going for, the oil tank was relocated inside the seat. A new rear hoop was manufactured, angled upwards towards the rear to accommodate the rear tire and rearward lighting setup. The swing arm was also given the satin powdercoat treatment, after being mounted up with new bronze bushing.

It was decided to keep the original RD tank for the build, albeit with custom knee pads and decal set. A fibreglass seatpan was fashioned up to match the lines of the tank and the new headlight, and an Ultragel pad cut to size at B & M Upholstery. The choice of the Ultragel is primarily for rider comfort, with the pad able to absorb the vibrations of the two stroke engine cycle. The front fender has been cut down to the minimum size that still supports the front forks, the rear stock fender has been replaced with one that matches the front fender, and both were powdercoated in satin black to match the frame. Finally the tank, seat and headlight cover were given a coat of the Ford colour ‘Toreador Red’, to offset the dark colouring of the lower part of the machine.

The controls and electrics have had a good work over as well. The factory headlight has been ditched, in it’s place is an LED unit, cased in a housing which complements the lines of the tank and custom seat pan. Another addition is a set of low rise handlebars, fitted up with new grips and switchgear, and the aluminium levers anodised in black. To give a more sporting riding position, a pair of KamiKaze Moto rearsets are mounted where the passengers foot pegs were located, with the kickstart lever modified to suit.

For an improved ride, the front end has been rebuilt with Racetech springs, and fork caps with preload adjusters to allow for fine tuning the rebound. The back end is mounted up with Assault brand shocks that are half an inch longer than standard. This, matched with the front forks being dropped 0.75 of an inch, puts a lot more weight on the front wheel, helping with cornering and turning capabilities. The front and rear brake cylinders have been replaced, pumping the stop stop juice through stainless lines to new repro brake calipers. Finally, the rotors were cross drilled and countersunk to allow for better heat dissipation under harder riding conditions.

With so much touched up, but still keeping that ‘true RD spirit’, Rusty Bolt Garage have produced a bike which really stands put. A multitude of modifications have created a bike which looks good and goes hard, with a lot of work carried out inhouse allowing the build brief to be followed as closely as possible. Helped along by the fact the RD is an awesome platform for a custom, it has culminated in a build to be proud of.