Written by Mark Turner.

In the sleepy town of Sandy in Bedfordshire in the UK, lives Chris Baglin, owner of Merlin Engineers Ltd. Merlin specialise in historic aviation and motorsport fabrication and repair. Around 8 years ago, one of Chris’ mates had an Egli Laverda. For those of you who aren’t familiar, Fritz Egli was a motorcycle racer turned custom frame builder. Amongst others, he built 25 Egli frames for the Laverda 750SF. Very rare and very beautiful and one of these bikes was the inspiration for what you see here.

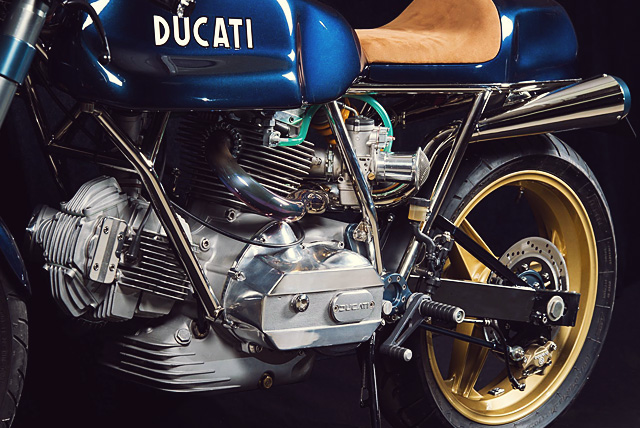

Chris’ mate had a spare Egli frame (as you do) which started cogs turning in Chris’s brain, thinking his spare Ducati Bevel engine might fit. Sadly, it was not to be, but the seed was well and truly sewn and Chris decided to utilise his extensive fabrication expertise and make his own frame. Based on the Egli frames of the 70’s, Chris’ frame is pure art, manufactured using 4130N aircraft grade chromalloy seamless tube.

The frame is flawless and Chris tells us fabricating the frame was quite straight forward but as always, the devil is in the detail. The spindles, headstock and swing arm pivot points were a challenge, sucking up a serious amount of fabrication time. There are around 60 bush’s, spacers and spindles in these 4 points alone which took longer to fabricate than the actual frame.

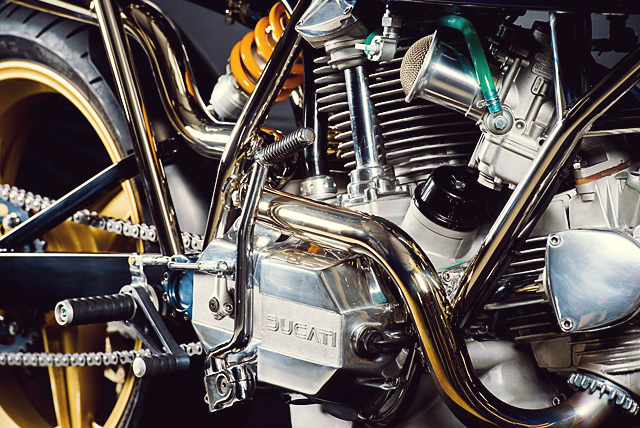

One of the many defining features of this bike are the exhausts. Chris wanted the exhaust up high but didn’t want the heat issues associated with running them this way. His solution was to route the exhausts inside the frame, best of both worlds.

There are a huge number of man hours invested in the exhaust, created from a series of bends and straights, welded, linished and finally nickel-plated. The silencers are manufactured by hand, rolled from flat sheets and fitted with machined end caps. You would be forgiven for thinking the exhausts were simply machine formed but Chris fabricated every inch by hand, from header to the tip of the silencer.

While we’re talking about in-house and hand-made, machined components, take a minute to look at the quality of the rear sets, top yoke, disc carriers and engine frames. All hand-made and all beautiful.

It will not surprise you to hear that the tank, based on the Imola style tanks raced in the 70’s, is also a hand-made item, skilfully crafted out of 1050A alloy making it light but soft and the seat unit is a bespoke glass fibre unit. To keep the clean lines, Chris has used a Motogadget system for the electronics, very neat, very clever.

This beautiful bike is certainly not all show. Chris has made sure there’s plenty of go and it comes from a heavily modified 900GTS 863cc ‘bevel’ L-twin. The ‘square case’ short stroke engine gets its name from the overhead cams, driven by a set of bevel gears and uses valve springs for closing (non-desmo) it also has those ‘Ital’ designed outer engine covers by Giorgetto Guigiaro of Studio Italdesign.

This ‘bevel’ engine has received more that it’s share of Merlin Engineers attention. It’s fitted with a race crank, Carrillo rods, big valves and lumpy cams and runs on silent Hektik ignition. It’s ported and sucks air through a pair of big 40mm Dellorto’s so she goes quite well and sounds awesome.

She rolls on classic lightweight Dymag CH3 wheels with upside down WP forks and there’s an Ohlins Shock holding things up at the rear.

Chris is happy to consider commissions if you fancy a beautiful piece of automotive art like this for yourself. And let’s face it, if you didn’t you’d have to be dead inside.

[Photos by Gareth Squance]