.

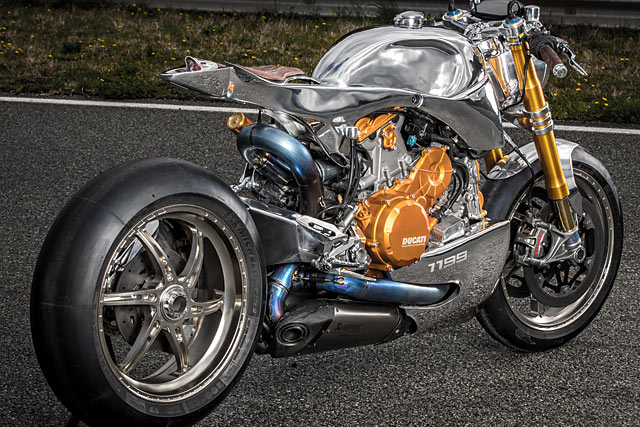

In Terminator 2, Arnie sat astride a leather and chrome Harley that was the perfect fit for his T-800 role. But had the studio commissioned a machine for the liquid metal T-1000, even the most creative Hollywood minds couldn’t have envisioned a bike like this. In a 2014 Ducati 1199 S Panigale, you get the same sort of technological leap over the old Fat Boy that the new T-1000 offered up. But where the stock red Ducati gets it all wrong visually, this insane alloy bodywork with its liquid-like flow would have scored a Skynet tick of approval. It’s quite literally a killer racing custom, and it comes to us from the brilliant minds at France’s Ortolani Customs.

Working with aluminium is the metalworking equivalent of trading in marble for clay. But if you’re old enough to remember the movie ‘Ghost’, you’ll know pottery can be pretty sexy. Like its slippery clay counterpart, aluminium is lighter, more malleable and capable of being formed into almost any shape.

So why don’t more people use it over steel? AMD winning alloy God, Scotty’s Choppers explains. “Any mistake when you come to polishing it will show up like dog’s balls, so it’s got to be perfect.” K9 testicles aside, the lads from Ortolani had faith in their ability to make an all-alloy Ducati work. And just like the T-1000, the flawless flow of this highly polished piece is absolute perfection.

Since 2009, Olivier, Gilles and Maxime have honed their skills at their base just north of Nice, creating an array of custom cars and bikes under the Ortolani banner. And if one thing has built their reputation, it’s the beautiful paint jobs they lay down. They’re equally capable of old school pin striping and gold flake right through to modern carbon fibre-infused race bike replicas.

But when a customer arrived at the shop with a drawing of a Ducati 899 in a holographic finish, it got tongues wagging. The idea was to take this most modern of motorcycles and purify it into a raw, minimalist and uncompromising mechanical masterpiece. The sort of machine that packed futuristic technology with old school craftsmanship into a single harmonious piece.

The holographic drawing would prove inspiration rather than gospel as Oliver points out. “We followed the spirit of this concept without following the lines, because the journey between a drawing and reality usually proves impossible to realise exactly.”

Then with the Ducati stripped of its clothes, the boys could begin to see exactly where they’d need to lay their alloy bodywork. The modern machine uses a monocoque design and the engine as a stressed member, so each panel would have to be self-supporting rather than having a steel frame foundation underneath. In other words, the challenge had just been doubled.

With tools at the ready, each sheet of alloy is hand beaten, shaped and then hand rolled before being offered up to wooden bucks until the match was perfect. The tank plays the most pivotal of rolls. Despite resembling a race tank of old, the swooping lines and weld-less finish still has to deal with both supporting the electronic fuel injection components and act as a cover for the enormous Ducati airbox. As a single piece, the sheer labour involved would make this tank worth many thousands of dollars, but it couldn’t work on its own.

To tie the tank in with the rest of the build, the bulk of the bodywork was then separated into two highly complex pieces. That they’re shaped from single sheets of alloy defy what most people believe is possible.

The first wraps around the steering stem and neatly covers where the front section of the bike is bolted to the engine. The second forms the tail; extending reward, the exquisite lines have a smoothness as if they were clay turned on a wheel. The dramatic rear section provides the perfect recess for a tail light without a single gap in the metal.

Then a number of covering panels were formed. The first acts as air scoops on each side, reminiscent of the more aggressive Buell creations. And the belly pan with its integrated radiator cover neatly hides many of the engine’s unsightly components while also centralising the visual mass.

The final touch might be small, but the front fender is both liquid metal smooth and razor-like in its design, and one can only be left speechless at the sheer quality of the work. Not wanting to sell the bike short, master saddle maker NMB Designs was tasked with creating the rustic floating leather seat and matching hand grips.

Suddenly, with all that aluminium as a contrast, the Ohlins suspension in its ubiquitous gold looks better than ever. But this isn’t just any ordinary Ohlins setup – if such a thing exists. Being the S model, this one comes with all the fruit. The front forks are electronically controlled NIX30 43mm units with TiN, or a Titanium Nitride coating.

But the acronyms don’t stop there, as the rear is a legendary TTX36 shock all controlled by the Ducati Electronic Suspension system. It seems that Ortolani’s love of exotic materials can even out do the Swedes, as the factory spring has been replaced by a raw titanium unit.

And if you haven’t realised already, they were really not mucking around when it came to weight saving and the bike’s stoppers. The factory setup with the Brembo radially mounted M50 monoblocks is designed to satisfy even the most fastidious of Ducati buyers. But Ortolani weren’t that impressed, so the 330mm discs have been swapped for carbon ceramic items for a little MotoGP madness.

And the search for perfection bordering on the insane doesn’t even stop there. Having upgraded the Ohlins and Brembo’s, the Marchesini wheels were next. In their place are a stunning set of lightweight OZ Racing forged rims wrapped in the latest racing slicks from Michelin.

With real mechanical excellence now pulsing through its veins, the Panigale doesn’t let the side down when it comes to the engine department. The 4 valve 90° L-Twin features some of the largest pistons in the motorcycle game, with an increase in capacity to almost 1200cc thanks to two massive new 112mm slugs. With an electronically controlled and rider-aided 195bhp on tap, you’d think that would be enough. But no.

Once again our three Frenchmen have wound up the wick with a full titanium Akrapovic racing exhaust system. And the visuals of the water-cooled centrepiece are perfected with a touch of Ohlins gold on the valve covers and sides, with many more hours of polishing put in to complete the look. Fine tuning the beast was taken care of by Motopolis in Nice, and the result is more than two hundred ponies. Quite a lot more, actually.

The brilliant factory dash remains, but is given a new alloy mount so it lies down, keeping a low profile. And you can’t have a set of keys jangling around on a bike this neat, so they wired in a Motogadget m-Lock. With the front end now a far cry from the way it left the factory, the lads could have simply grabbed a 7″ headlight, had a beer and called it a day. But it’s just not their style. So the finishing touch is a yellow-lensed unit housed in a custom crafted alloy surround that exquisitely includes a meshed air intake. Ever seen that before? Neither have we.

Then out came the polishing rags for the hundreds of hours of elbow grease required to produce such an incredible, liquid-like finish. More than ten years on from Scotty’s Choppers all alloy success at AMD, Ortolani Customs has a Ducati that could easily take home the trophy, race around Monza at incredible speeds, and then have a T-1000 climb aboard it to terrorise the world, but this time with a whole heap of cool French style, to boot.

[ Ortolani Customs – Facebook – Instagram | Photos by Julius Designs & Arnaud Vantaggi ]