“That bike’s a classic!” It’s a phrase we hear all the time, and often it’s used far too flippantly for its own good. But if we were to use a, erm, classic definition of the word ‘classic’ it would mean that for any bike to truly deserve the title, it has to be ‘of an exemplary standard within a traditional and long-established form or style.’ Of course, many of the bikes that grace our pages are far from being traditional in form. Hell, some are the exact opposite of that. But for the lucky few who do live up to the title, adoration of a bike that we know will look as good in 100 years as it does right now awaits. And the latest candidate for the title? Meet MONNOM’s latest, a classic Honda CB550 cafe racer if ever we saw one.

Based in Des Moines, Iowa, MONNOM is the sole creative work of Mike Gustafson. “My wife Sandy and I also own and operate Nestcraft Studio, which creates high-end custom furniture on a commission basis. So I applied the same design aesthetic and attention to detail I use on my furniture commissions to create this project.” Mike does some mechanical work, specifically on early to mid 70’s Honda motorcycles for friends and fellow cafe enthusiasts, but he is most interested in creating classic, well-proportioned cafe racers with some modern performance upgrades.

So many builds these days are utilising large, inverted forks and modern swing arms; sure they look amazing, but sometimes it’s easy to think that the classic cafe bike has got a little lost in all the noise. As have some of the more traditional materials. “I am currently working on another custom build, a 1973 Honda CB 350 twin, which will expand on the use of wood. I guess you could say that the combination of would and metal is something that really interests me.”

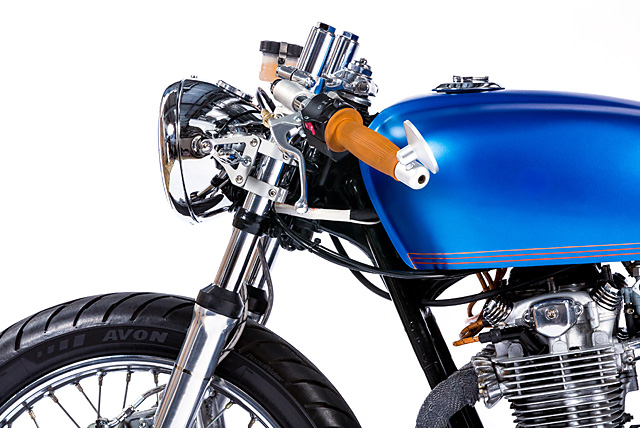

This build began with a very sad ‘78 Honda CB550. The tank was in spectacularly rough condition, the electrical system was a mess and the engine had about as much compression as an antique garlic crush. The build began by stripping the bike down, cleaning things up and establishing some sort of logical starting point. “The tank had been poorly altered by a previous owner, which included removing the recessed locking fuel cap cover and filling the remaining holes with scraps of tin can and Bondo.” Tell us they have the death penalty in Iowa, please. “My fabrication work began by removing the top portion of the CB 550 tank and replacing it with the top section of a CM 450 tank. I welded on the raised upper section and body worked the fillets, giving the stock tank a much more aggressive look.”

Then turned his attention to the electrical system. “Sparck Moto supplied a custom loom to my specifications that included an upgraded regulator/rectifier unit. I then installed a new set of left hand controls with a simple on-off switch relay. The large-ish 7″ headlight was the perfect size to custom flush mount a Motogadget Motoscope Tiny gauge.” Mike then installed an LED rear light strip with a dual intensity circuit by Custom Dynamics, along with small LED turning indicators. A tiny 4 cell lithium-ion battery is tucked under the seat cowl and it supplies enough cranking amps to easily start the bike. An electronic ignition from Dyna and a new set of 5 OHM Dyna coils finished off the electrical side of things nicely.

“I rebuilt the top end of the engine with new rings, a cylinder hone, gaskets, cam chain slipper, seals and a valve job. The engine cases were then hand polished and the motor was painted, too. A freshly powdercoated, plated and polished set of CB 500 carburetors replaced the stock carbs that were literally falling apart.” Mike then wrapped a new set of MAC 4 into 1 headers and added an 18″ reverse cone stainless steel slip-on from Cone Engineering. CNC aluminum rearsets were installed with hand-fabricated linkages and the clutch basket was also rebuilt to Mike’s exacting specs.

He then added a second front rotor and caliper, and upgraded the master cylinder to a new Nissin 14mm piston which added a much-needed increase in front braking power. Next came drilling both the rotors to visually lighten up the front end and reduce the bike’s weight a little. “The front forks were rebuilt with new seals and progressive fork springs, the rear shocks were upgraded to 360mm units and the fuel tank position was also modified to give the bike a much more aggressive stance. I dropped one tooth off the front sprocket to liven the low-end of the bike and a new chain and rear sprocket smoothed out the rest of the power.”

The rear subframe was chopped off and a seat hoop was welded in. “I shaped the rear seat cowl from foam and clay and laid out several layers of biaxial fiberglass and epoxy resin. The seat pan was then ready to receive a hand shaped solid Cherry wood seat I made. The wood was rough cut on a bandsaw and the final shaping was done with hand tools. The tank was body worked and then painted with a custom combination of House of Kolor ‘Shimrin’ base color and a matte 2K clear. The bronze pinstripes were laid out by hand and I finished by sorting out the rest of the smaller details.”

The resulting bike is one that has about as much chance of ageing badly as Plato or da Vinci have of becoming the latest thing to be embraced by the cool kids – and we wouldn’t want it any other way.

[MONNOM: Web – Instagram | Photos by Erich Ernst]